Why a UL Listing Matters

Founded in 1894, Underwriter Laboratories is the standard in America for safety and quality assurance. Our products undergo thorough and rigorous testing in these independent facilities. This commitment to quality allows us to provide some of the best warranties in the business, and helps to ensure that your sign is safe regardless of electrical and environmental conditions.

-

UL engineers validate, test and certify our products down to the component level.

Failure testing is conducted where parts such as fans are intentionally disabled.

Our complete signs are tested as a whole, not just individual components.

Production facilities require inspection by UL engineers for certification.

MET and others are not equivalent. UL is considered the authority by all.

Look for this symbol on your next electric sign!

Each product and component undergoes a variety of safety tests with specific protocols. The main focus of these tests are stability and predictability, that if circumstances cause a component to fail, it does so without causing harm.

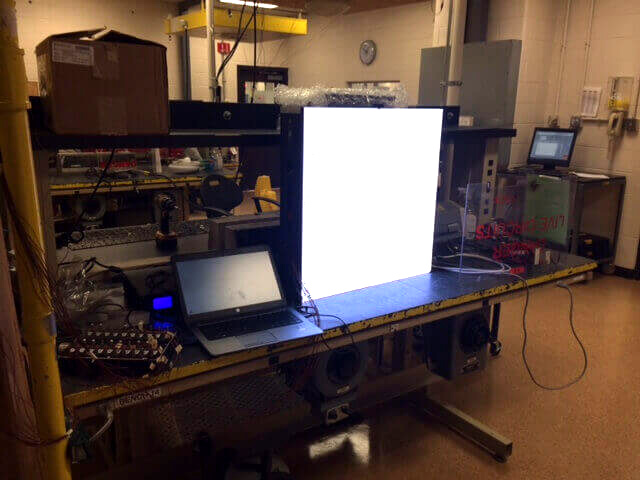

Each product is subjected to a battery of environmental conditions over several days. These include stress tests where up to ten times the standard voltage is applied to trigger failsafes and check for electrical leakage. Internal temperature is monitored and materials tested to see that they don't degrade in extreme environments.

Spark and combustibility testing is conducted should flammable material such as bird or insect nests ever make it into the sign cabinet. Devices such as fans, motherboards and power supplies are intentionally short circuited or disabled to check for effects on internal temperature and proper operation.

Multiple UL engineers validate, test and certify our products down to the component level, meaning that all materials and devices must be independently UL Listed themselves. Whether it is the controller for our LED signs or the rubber gasket around the edge of our sign cabinets, each part must pass a technical review by the most scrutinizing engineers in the industry.